We are producing automotive parts for the leading manufacturers in the automotive sector led by Toyota

read moreSango aims at embracing the future as a global automotive parts manufacturer. Our sole aim has been production since the first day of our establishment.

read more

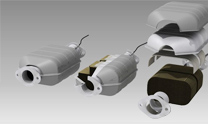

Designing automotive system is a core technology at Sango, which makes use of an independently developed expertise in acoustics accumulated through long years of experience. This incomparable cornerstone of our technology is freely put to use when designing a muffler structure, which must be capable of responding to the needs for both engine power and noise attenuation, two requirements that naturally work against each other and, when seeking the optimal placement of each noise attenuation and conversion component within the system.

Sango also independently develops its own materials, in order to ensure that physical property requirements for products and their production processes are met. In particular, stainless steel used for exhaust systems must be able to withstand high temperature environment and Sango works together with raw material manufacturers to develop low cost material with high quality functions.

To developed an exhaust system that will provide maximum performance, Sango optimizes the physical placement of such components as the exhaust manifold, mufflers, and cataltic converters, intergrating each component into a total system which will meet all targets for function, durability, weight and cost.

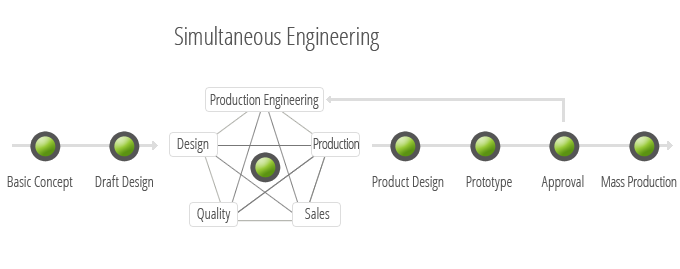

The Design Division is made up of the advanced engineering and product engineering departments, who interact with each other, along with the production engineering and quality department realizing an efficient and optimal design process.

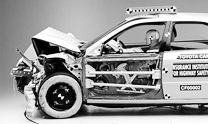

All the equipment and facilities necessary to validate a product's performance and reliability are available so that testing can be done in-house and provide immediate feedback to the designers. In addition, high quality analytic evaluation is carried out, using CAE* both to predict evaluation results and choose optimized solutions.

*CAE (Computer Aided Engineering)